About us

COMPANY PROFILE

Baovain Suzhou International Trade Co. Ltd is a professional OEM&ODM metal parts manufacture & exporter with more than 10 years of customization experience. We have two factories: Suzhou Zunlan Industry and Trade Co., Ltd & Wujiang Fenhu Kaisheng hardware processing factory.

Baovain in Suzhou, the "Venice of the East", Baovail integrates 1,000 years of Jiangnan casting heritage with modern industrial innovation. Specializing in premium cast iron counterweights for over two decades, we are a one-stop solution provider with an annual capacity exceeding 50,000 tons. Serving clients in 30+ countries, our precision casting technologies deliver customized counterweights for construction machinery, renewable energy systems, and shipbuilding – transforming every cast iron piece into the "anchoring force" of industrial equipment .Our products mainly include: Iron Castings, Stainless steel castings, CNC machining parts, sheet metal parts, stamping parts, etc. The factory has obtained ISO9001: 2015 quality management system certification. After more than 10 years of development, we have built up a professional engineer team and complete quality control system, such as dimensional inspection, chemical composition analysis, mechanical property tests, non-destructive tests and metallographic inspections, etc.

Sand casting is perhaps the oldest and most commonly used type of metal forming in the marketplace today. It is capable of forming both large and small parts and can be used for a number of different materials.

We have green sand castings, resin sand casings and water glass sand castings in both ferrous and non-ferrous materials

Perhaps the most common green sand castings would be made from either grey iron or ductile iron. We can supply these castings from approximately 0.05Kg to approximately 15000 Kg and up to 5000mm x 2000mm x 1500mm in size for the largest part. Molding methods range from floor hand molding, jolt squeezer lines and automatic molding lines. With this variety of molding methods we are able to accommodate the weight, size and quantity the customer requires. Steel sand castings are available both as water glass sand castings and resin sand castings, and are available in plain carbon, alloy and stainless steels. In the category of steel sand castings the smallest available part would be approximately 1Kg while the largest would be approximately 20 tons. Steel castings smaller than the 1Kg range would be made from investment casting(lost wax casting) method. Non-ferrous sand castings are also available. The molding process used is green sand and we can accommodate requests for castings weighing from 0.1 Kg to 100 Kg. The alloys that are available include copper base and aluminum base alloys. First article layouts and spectrometer material certifications are provided with all first article samples. Specialized inspection reports can be done per customer request. A variety of secondary operations can be performed on all three types of sand castings. They include shot blasting, heat treatment, machining, surface treatment, assembly services and even custom packaging.

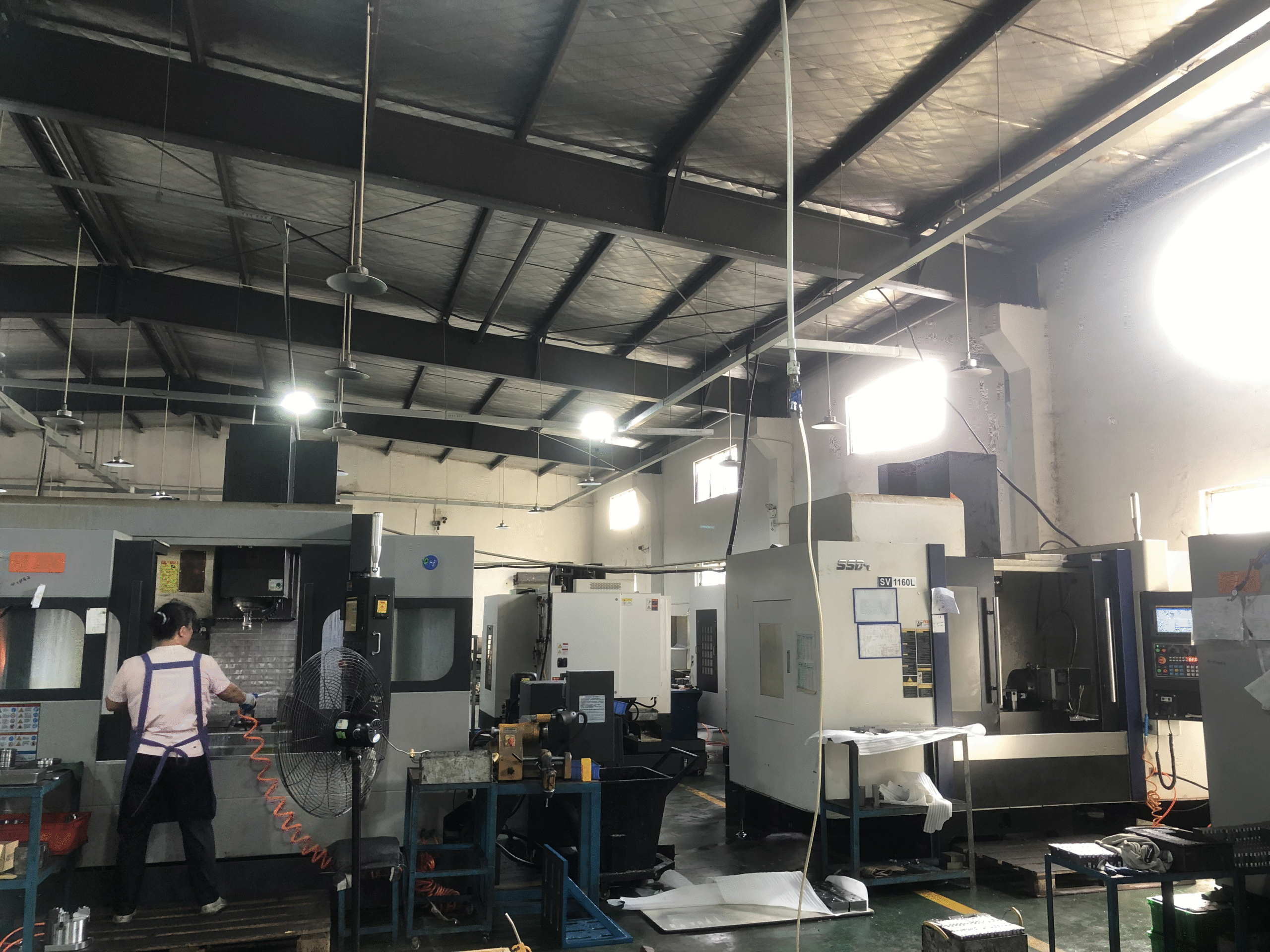

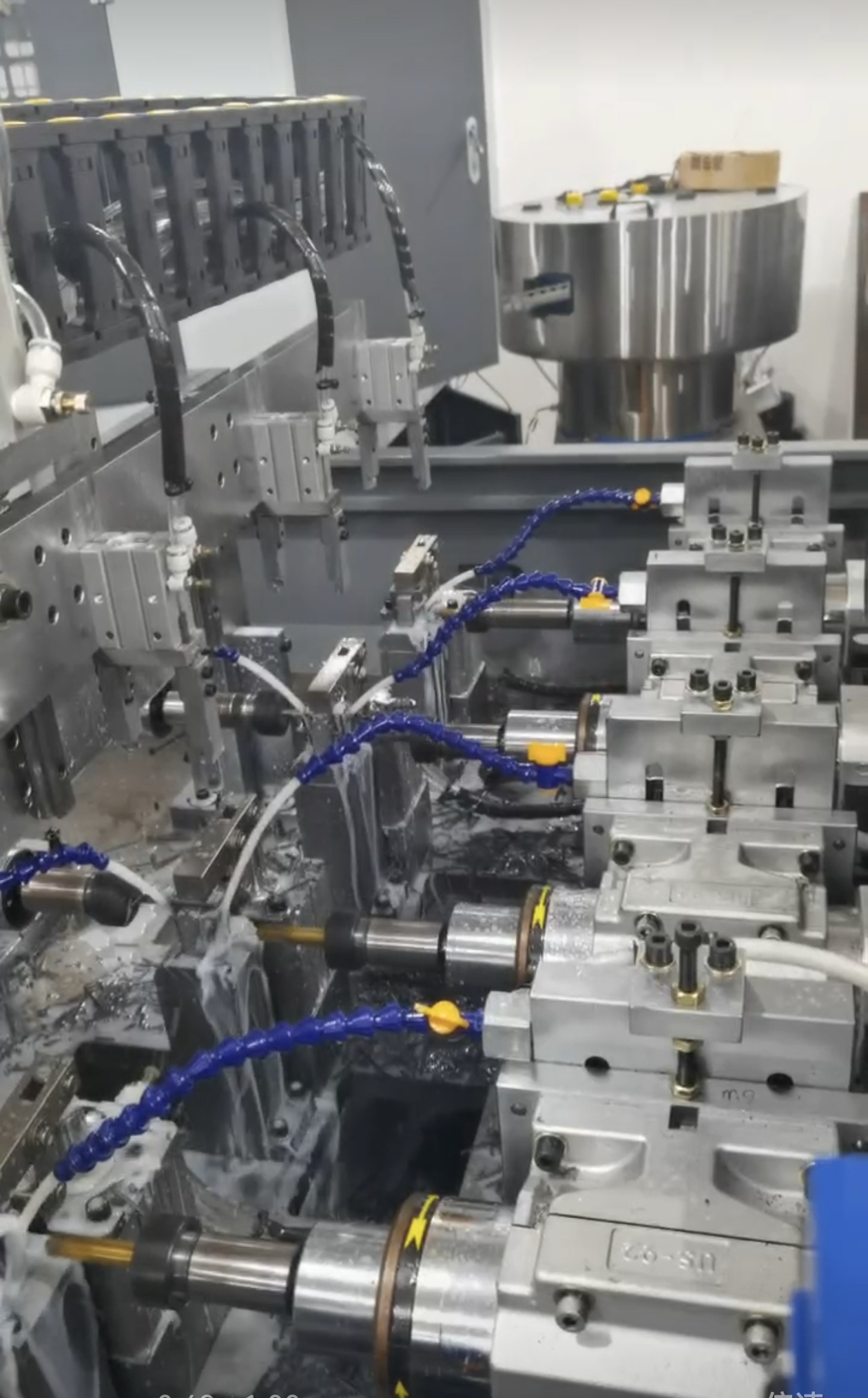

Our Facilities